Transforming industrial CO2 emissions into clean energy and valuable resources.

Transforming industrial CO2 emissions into clean energy and valuable resources.

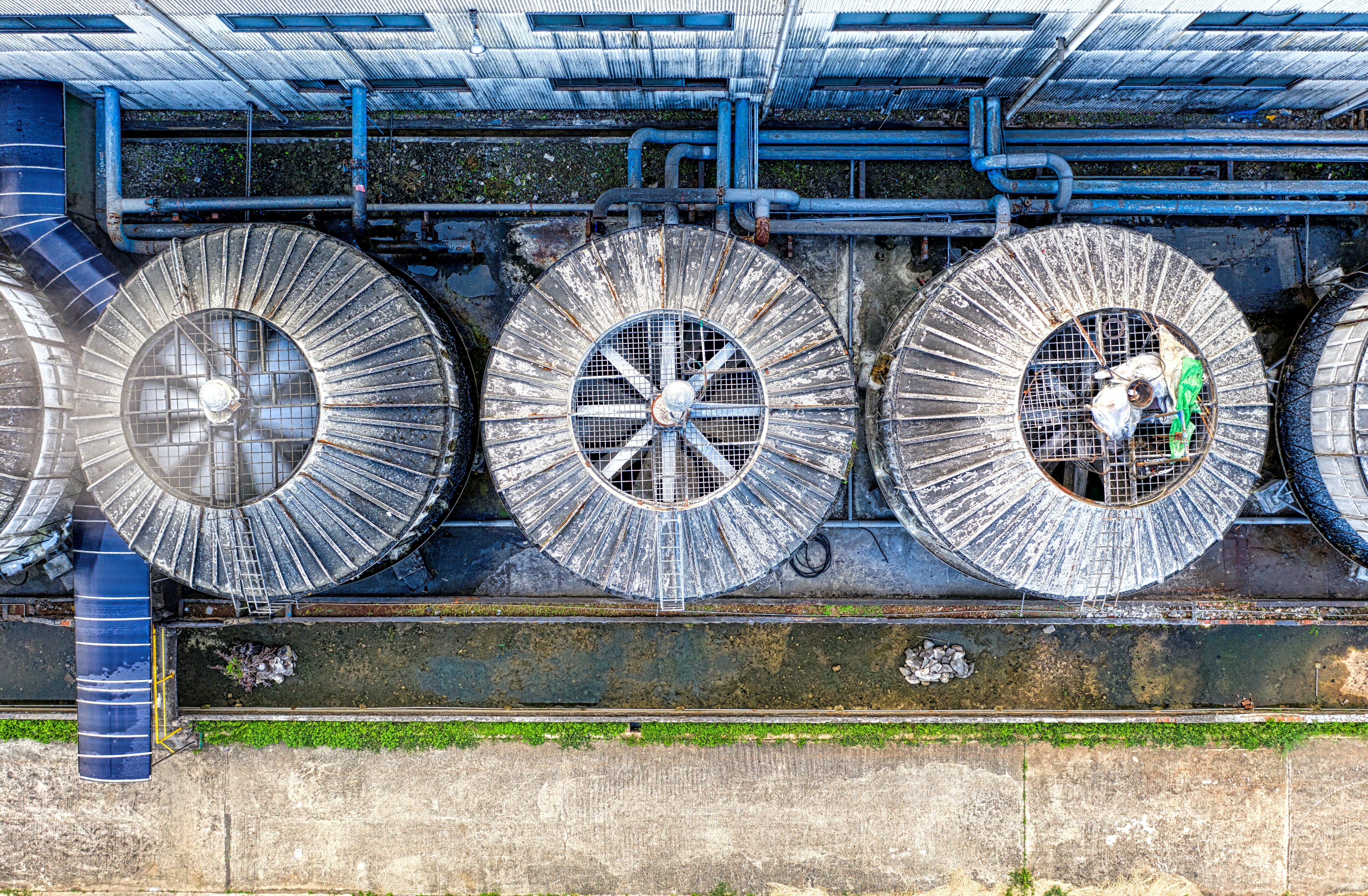

We capture CO₂ from industrial facilities and factories to produce hydrogen for a cleaner, circular economy.

We capture CO₂ from industrial facilities to produce clean fuels like Hydrogen and Methanol

Challenges

Challenges

Challenges

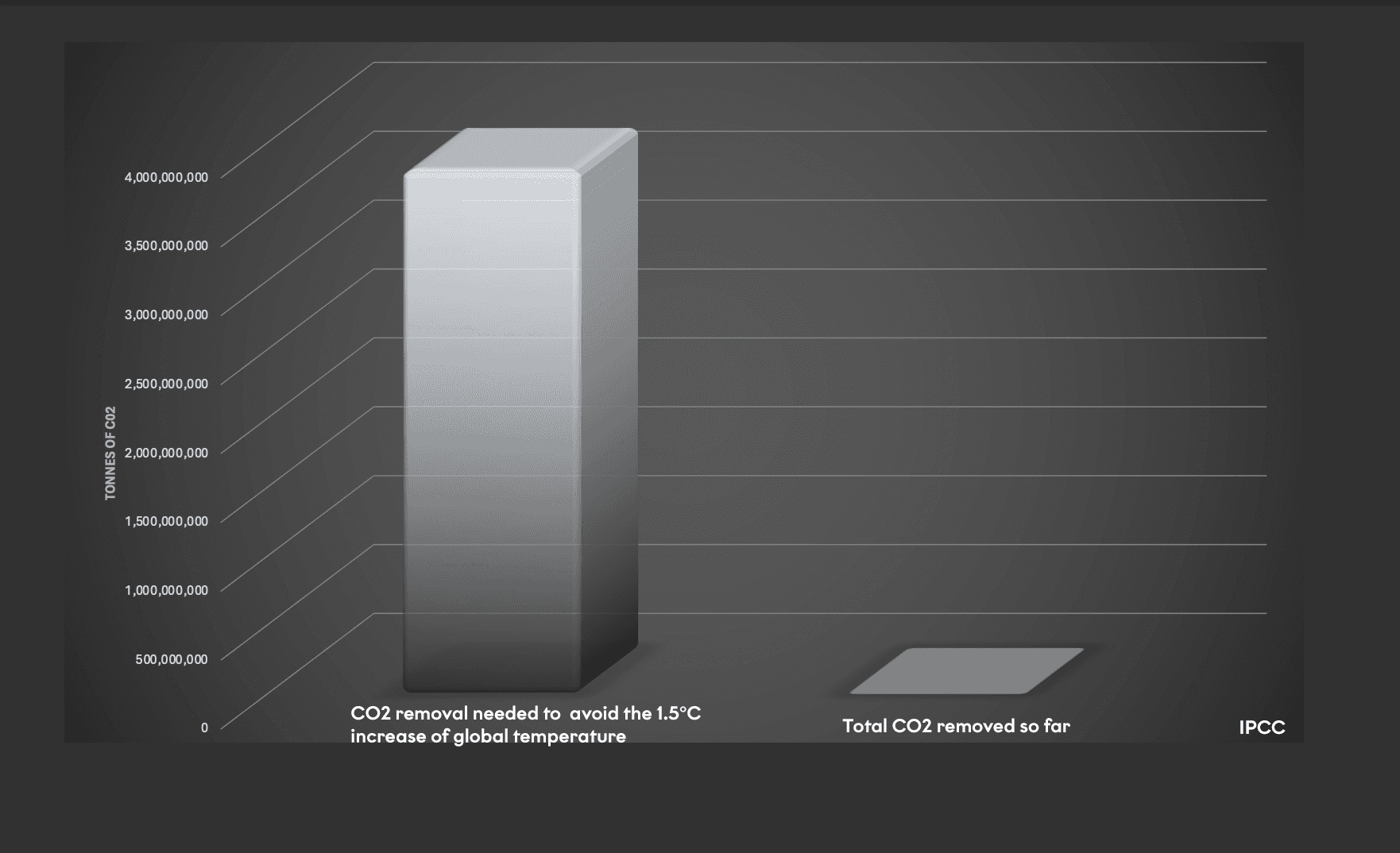

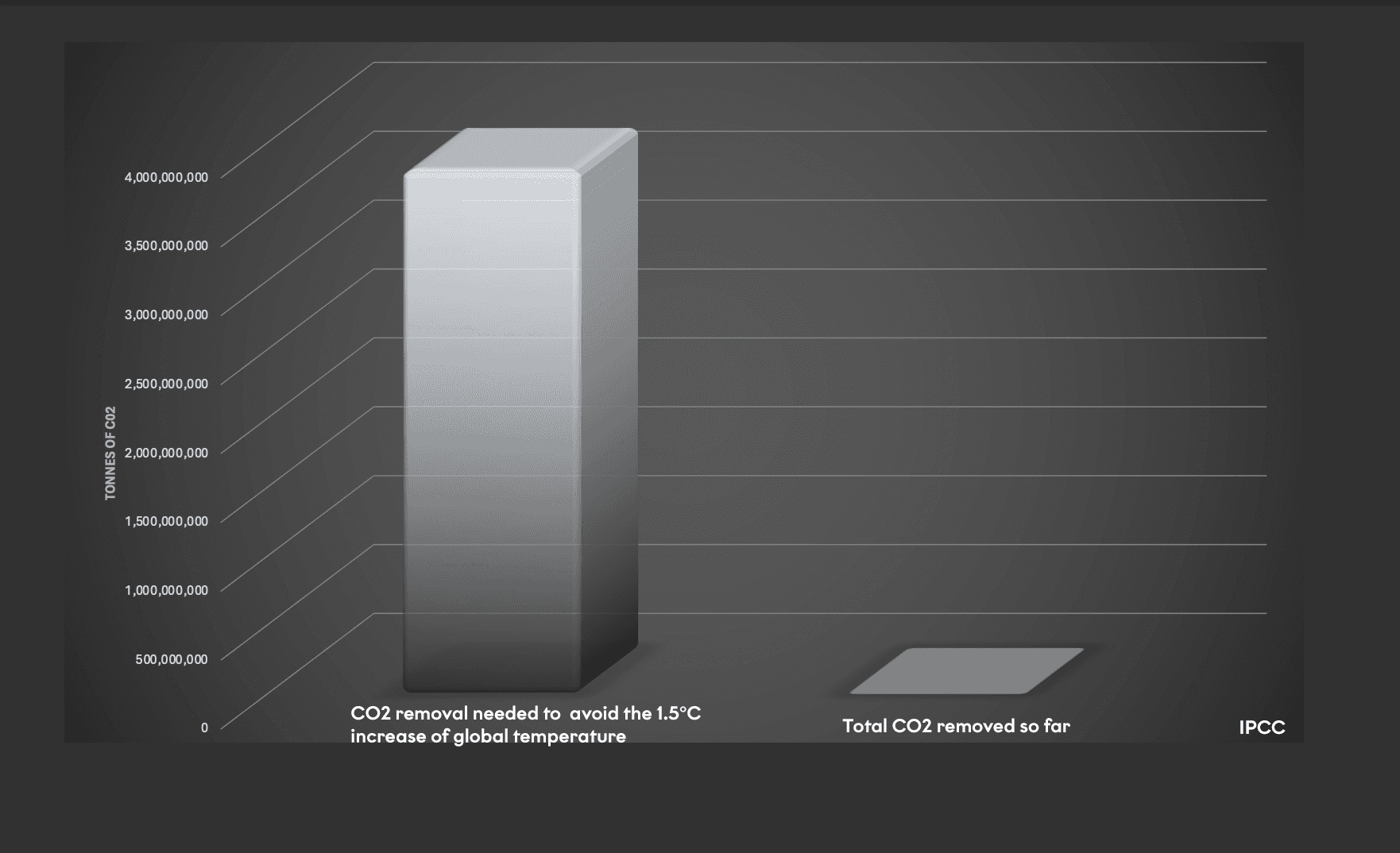

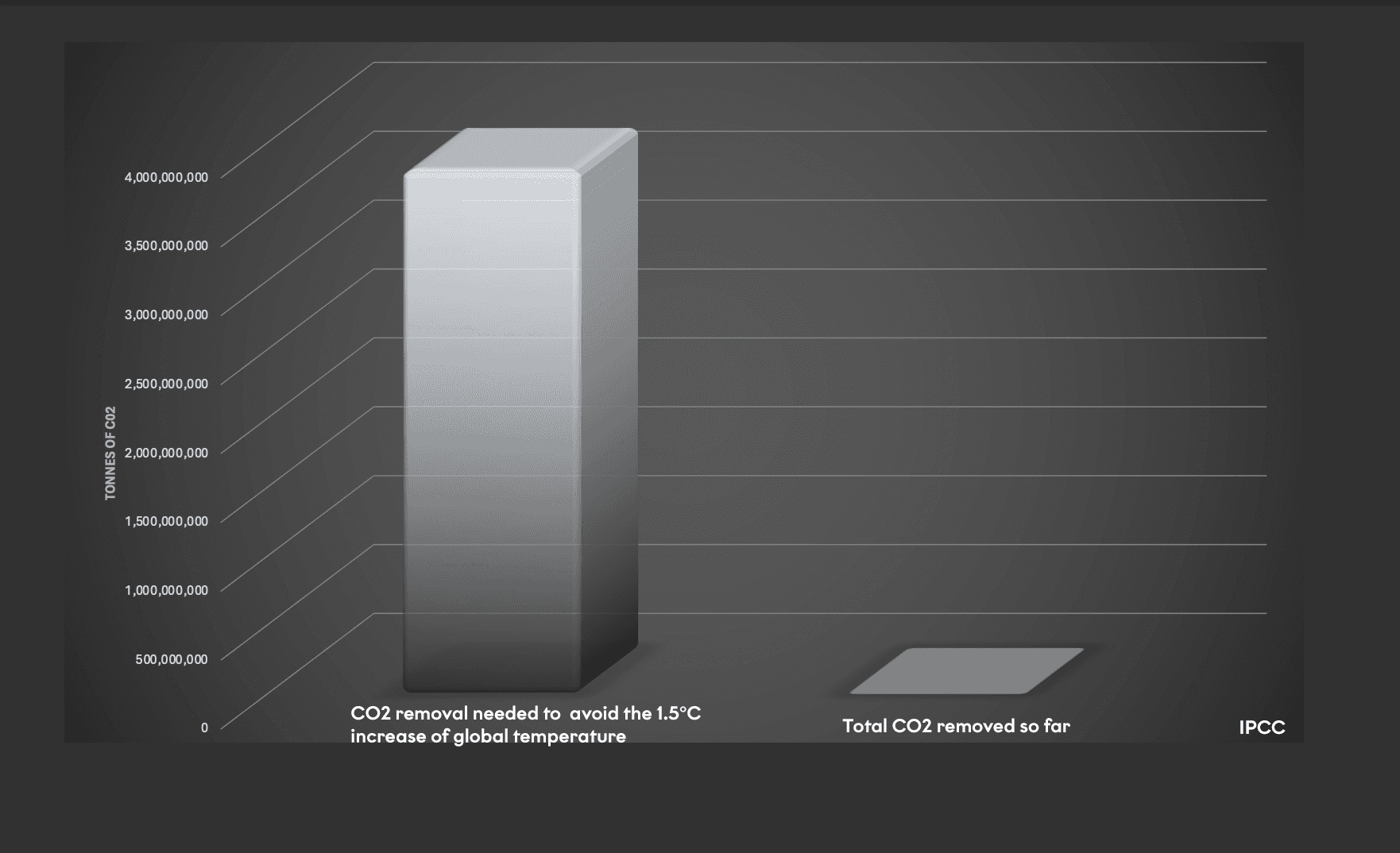

Biomass carbon removal and storage (BiCRS),Trees, Direct air capture (DAC), Ocean-based carbon removal are the most common Carbon dioxide removal (CDR) methods but they are not enough. The stark contrast between emissions and capture highlights the need for more aggressive and effective measures in carbon capture and reduction

Challenges

Challenges

The stark contrast between emissions and capture highlights the need for more aggressive and effective measures in carbon capture and reduction

ENERGY PLANTS

FACTORIES

CONSTRUCTION

METALLURGY

MANUFACTURING

ENERGY PLANTS

ENERGY PLANTS

FACTORIES

CONSTRUCTION

METALLURGY

MANUFACTURING

ENERGY PLANTS

Our technology

How we handle the problem:

CO2 conversion into clean energy as a Service

CO2 conversion into clean energy as a Service

Our technology

How we handle the problem:

CO2 conversion into clean energy as a Service

Clustaer offers a breakthrough solution that captures CO₂ emissions from industrial sources (point source) before they are released and converts them into valuable products like Methanol and Hydrogen.

Using a unique combination of electrochemical reactions and advanced gas-separation technology.We design an end to end pipeline of co-electrolysis to maximize the effciency of CO2 conversion into Hydrogen and other useful byproducts .

Clustaer offers a breakthrough solution that captures CO₂ emissions from industrial sources (point source) before they are released and converts them into valuable products like Methanol and Hydrogen.

Using a unique combination of electrochemical reactions and advanced gas-separation technology we develop a novel CO2 transformation paradigm: We design a specific pipeline of

co-electrolysis to maximize the efficiency of GHG transformation into clean and useful byproducts.

A cutting-edge efficient CO₂ electrolyzer system that transforms industrial emissions and into high-purity clean energy fuels.

A cutting-edge CO₂ and water co-electrolyzer system that transforms industrial emissions and into high-purity clean energy fuels.

Modular Design: Scalable pipelines with gas separation and electrolyzers tailored for different industry sizes, from small factories to large-scale operations.

Modular Design: Scalable pipelines with gas separation and electrolyzers tailored for different industry sizes, from small factories to large-scale operations.

Neutra-1

Powered by renewables

As Clustaer scales it can bring the capability of powering itself with the clean fuels it produces or with a hybrid solar setup.

Powered by renewables

As Clustaer scales it can bring the capability of powering itself with the clean fuels it produces or with a hybrid solar setup.

Neutra-1

Powered by renewables

As Clustaer scales it can bring the capability of powering itself with the clean fuels it produces or with a hybrid solar setup.

Novel catalysts

Our bet is the discovery of more performant, reactive and non toxic electrolysis processes & materials.

Novel catalysts

Our bet is the discovery of more performant, reactive and non toxic electrolysis processes & materials.

Direct mitigation carbon credits

Direct mitigation credits rather than offsetting or compensation, enables companies to earn carbon credits by capturing CO₂, offering fiscal & financial incentives.

Direct-mitigation Carbon Credits for Industries

Direct mitigation credits rather than offsetting enables companies to earn carbon credits by neutralizing CO₂, offering fiscal & financial incentives

ENERGY PLANTS

FACTORIES

CONSTRUCTION

METALLURGY

MANUFACTURING

ENERGY PLANTS

ENERGY PLANTS

FACTORIES

CONSTRUCTION

METALLURGY

MANUFACTURING

ENERGY PLANTS

Main use cases

Main use cases

Main use cases

The IPCC’s latest reports outline the scale of the challenge, saying that limiting warming to 1.5C translates into around 6 GtCO2 of CDR per year by 2050. To put this into perspective, that is more than the weight of all petroleum produced today, a monumental endeavor.

The IPCC’s latest reports outline the scale of the challenge, saying that limiting warming to 1.5C translates into around 6 GtCO2 of CDR per year by 2050. To put this into perspective, that is more than the weight of all petroleum produced today, a monumental endeavor.

The IPCC’s latest reports outline the scale of the challenge, saying that limiting warming to 1.5C translates into around 6 GtCO2 of CDR per year by 2050. To put this into perspective, that is more than the weight of all petroleum produced today, a monumental endeavor.

"Meeting the recent pathways laid out by the IPCC will require total cumulative net carbon dioxide removals of 20-660 GtCO2 by 2100. This will require markets and governments to come together to invest significantly into sustainable business models. While challenging, this could also create an opportunity to build co-benefits including biodiversity benefits and equitable growth"

"Meeting the recent pathways laid out by the IPCC will require total cumulative net carbon dioxide removals of 20-660 GtCO2 by 2100. This will require markets and governments to come together to invest significantly into sustainable business models. While challenging, this could also create an opportunity to build co-benefits including biodiversity benefits and equitable growth"

McKinsey

"Meeting the recent pathways laid out by the IPCC will require total cumulative net carbon dioxide removals of 20-660 GtCO2 by 2100. This will require markets and governments to come together to invest significantly into sustainable business models. While challenging, this could also create an opportunity to build co-benefits including biodiversity benefits and equitable growth"

McKinsey